[custom_headline type=”left” level=”h1″ looks_like=”h2″]VitroTEM – Graphene liquid cells at a click.[/custom_headline]

Naiad-1

The Naiad-1 is VitroTEM’s benchtop device for automated GLC fabrication. Naiad-1 fully automates the preparation and handling of graphene, delivering efficient and reliable sample production. Easy-to-use software guides the user through the GLC assembly process. Naiad-1 makes the use of GLCs easy and attainable for any laboratory.

Transfer and automated GLC Fabrication

VitroTEMs properietary graphene transfer technology is based on Loop-Assited Transfer (LAT). Our technology does not require any assistant polymer layers or post-processing steps, delivering ultra- clean graphene without any polymer traces. Our clean and reliable transfer technology is ideally suited for assembling GLCs for high-resolution TEM imaging.

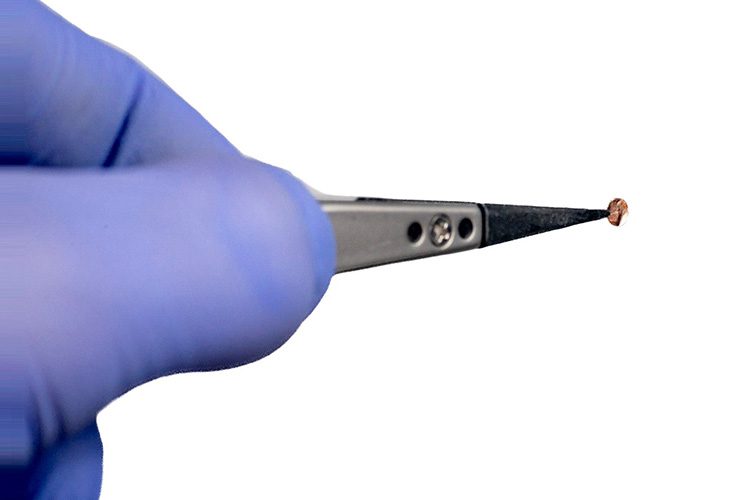

VitroTEM provides disposalble metal loops on a disposable cartridge that is mounted on the Naiad-1 by hand.

GLCs are formed by sandwiching a liquid sample between a top and bottom graphene layer. The bottom layer is supplied on a standard TEM grid available in two grades:

The TEM grid and a small blotting paper are held on a disposable cartridge that is mounted on the Naiad-1 by hand. Any type of aqueous sample can by added by pipetting a volume of 0.5 – 5 µl onto the TEM grid.

The top graphene layer is transferred onto the sample by automated loop-assisted transfer (LAT). After automated blotting, the GLC grid can immediately be mounted on a TEM grid holder and inserted into the electron microscope.

The CLG assembly process takes around 3 minutes.

Graphene

VitroTEM provides home-grown high-quality graphene that is quaranteed to deliver ultra-clean GLC grids with highly crystalline monolayer graphene and full grid coverage. VitroTEMs proprietary graphene is supplied on a small copper disk.

The Naiad-1 features a flow cell for the controlled etching of the copper disk preceding GLC assembly. The etching takes around 4.5h. Etching can be done overnight to have graphene ready for use in the morning. After etching, the graphene floats freely on the surface of the liquid in the flow cell.

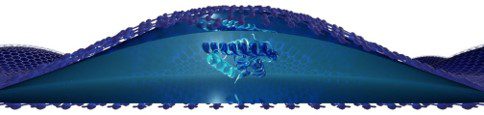

Graphene is an unrivaled substrate for transmission electron microscopy, offering optimal electron transparancy, efficient charge dissipation, as well as protection against beam damage. GLCs fully encapsulate liquid-based samples. The water- and vacuum tight graphene encapsulation allows liquid-phase imaging, enabling the study of dynamic processes in living biological cells and tissues, or analyse nanomaterials and single-nanoparticle analysis at atomic resolution.

Graphene Liquid Cells

GLCs are sub-micron size pockets of water trapped between two layers of graphene. VitroTEM brings GLC-technology as a standard tool for routine research in Liquid Phase Electron Microscopy (LPEM), enabling systematic exploration of aqueous samples.

GLC Kit

The GLC Kit contains all the necessary tools to fabricate a total of 5 GLC grids:

The Naiad-1 can simultaniously etch up to 5 Graphene-on Copper Disks in a single run. After etching, Naiad-1 can fabricate 5 GLC grids in a row or keep the remaining graphene on stand-by for GLC assembly at a later stage.

Fluids Pack

The Liquids Pack contains 4 bottles of proprietary fluids used for the etching of copper from the Graphene-on-Copper Disks. The Liquids Pack has a capacity for 7 GLC fabrication runs, providing a maximum production of 35 GLC grids per Fluids Pack.VitroTEM supplies a variety of commonly used buffers for the final stage of GLC assembly. During loop-assisted transfer of graphene onto the grid, minor dilution of the sample cannot be avoided. The use of buffer at this stage of the assembly ensures that the buffer composition and concentration in the GLSs is not affected. The Naiad-1 allows the use of users’ own custom buffer or medium.

Naiad-1 specifications

| Technology GLC | Graphene Liquid Cell fabrication on TEM grid by means of loop-assited transfer |

| size range GLC | 100-1.000nm (av.diameter) |

| Density | 10-100 GLC per µm² |

| Graphene quality | Ultra-clean single-layer highly crystaline graphene |

Process

| Etching cycle Etching | 4.5h hours |

| Capacity GLC fabrication | Up to 5 Graphene-on-Copper Disks per etching cycle |

| Time Graphene | 3 minutes per GLC grid |

| Deposition yield | > 85% |

| Graphene coverage¹ | > 95% |

System

| Dimensions | 380 x 355 x 520 mm (D x W x H) |

| Weight | 25 kg (excluding bottles) |

| Operating temp. range | 15-30 °C |

| Power usage | Up to 150W |

| Voltage PC | AC 110 – 240 V, 50-60Hz |

| requirements | Windows 10 or 11, 16 Gb RAM, 1x USB 2.0 (minimum requirements) |

Consumables

| GLC Kit – Standard | Consumable to fabricate 5 CLG grids: 5x Graphene-on-Copper Disk 5x Ultra-thin carbon coated TEM grid on a disposable cartridge 5x Transfer loop on a disposable cartridge 1x Graphene Disk Carrier |

| GLC Kit – Premium | Same as GLC KIT – Standard but with differnt TEM grids: 5x Single-layer graphene coated TEM grid on a disposable cartridge |

| GLC Kit – Ultra | Same as GLC KIT – Standard but with differnt TEM grids: 5x Single-layer, ultra clean graphene coated TEM grid on a disposable cartridge |

| Fluids Pack² | Set of bottles of proprietary fluids sofficient for 7 etching cycles: 1x Etching solution 1x Rinsing liquid 1x Ultra-pure water 1x Buffer (various standard buffers available) ³ |

¹ Graphene coverage of the imaging area of the grid.

² It is mandatory to exclusively use the Fluids Pack in the Naiad-1. The use of other fluids (other than the user’s own buffer or medium) may damage the device and will invalidate the warranty.

³ The use of non-proprietary buffer fluids may affect the quality and yield of the GLCs.