[custom_headline type=”left” level=”h1″ looks_like=”h2″]ELMO[/custom_headline]

Glow Discharge system for TEM grids

Your TEM grids ready within seconds.

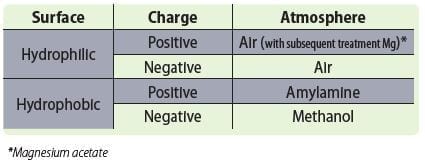

HYDROPHILIC OR HYDROPHOBIC, NEGATIVE OR POSITIVE CHARGE

- A Glow Discharge treatment with a specific gas atmosphere will modify the surface properties of TEM support films or grids in order to optimize the adsorption of the solutions to spread.

ELMO Brochure (29 downloads )

TEM carbon support films have a hydrophobic tendency.

A glow discharge treatment with air makes the carbon film surface negatively charged and hydrophilic which allows an adsorption of aqueous solutions.

Thanks to a glow discharge treatment with amylamine the hydrophobic tendency of the carbon film is kept and the surface is charged positively allowing an adsorption of molecules like nucleic acids.

BENEFITS

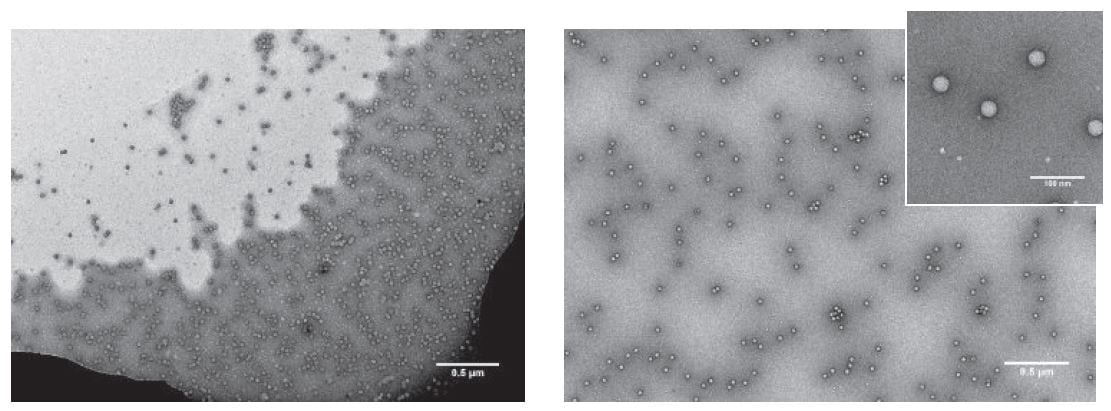

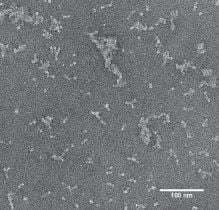

WITHOUT GLOW DISCHARGE

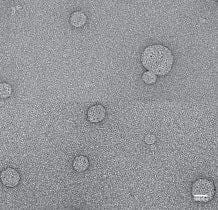

WITH GLOW DISCHARGE

Figure 1 : Negative staining with uranyl acetate of the viral capsids spread on a TEM grid without treatment.

Courtesy : M. Decossas, CBMN

Figure 2 : Negative staining with uranyl acetate of the Poliomyelite virus spread on a TEM grid with a glow discharge treatment with air (2mA during 40sec).

Courtesy : M. Decossas, CBMN

[text_output]

EASY

- Quick and easy loading of films or grids.

- Intuitive operation with manual or programmed mode.

- Affichage (courant, pression, durée) en temps réel des données sur écrans LCD rétrReal-time display of process parameters (current, vacuum, time).

[text_output]

FLEXIBLE

- Glow discharge methods : hydrophilic or hydrophobic,negative or positive charge.

- Dual vacuum Bell Jars to avoid cross contamination.

- Anti-implosion glass for an easy cleaning and a high secured process.

[text_output]

REPRODUCIBLE

- Accurate injection control of gaz or liquids.

- Accurate vacuum control using Pirani gauge.

- Soft venting (air or neutral gaz) using quick inlet fitting.

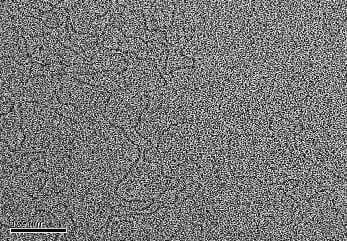

APPLICATIONS WITH GLOW DISCHARGE IN AMYLAMINE

Figure 3 : Negative staining with uranyl acetate and rotary shadowing with platinium of plasmid DNA.

Courtesy : C. Ruhlmann, IGBMC

Figure 4 : Negative staining with uranyl acetate and rotary shadowing with platinium of yeast chromatin.

Courtesy : C. Ruhlmann, IGBMC

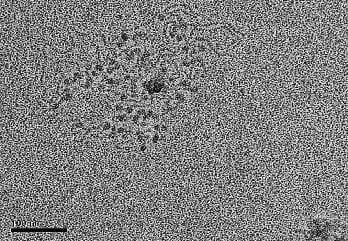

APPLICATIONS WITH GLOW DISCHARGE IN AIR

Figure 5 : Negative staining with phosphotungstic acid of Influenza virus hemagglutinin.

Courtesy: M. Decossas, CBMN

Figure 6 : Negative staining with uranyl acetate of liposome and proteo-liposome.

Courtesy : L. Daury-Joucla, CBMN

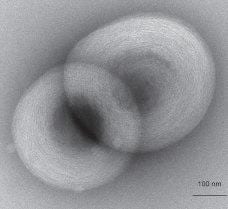

Figure 7 : Torus obtained by complex coacervation between the peptide P140 and hyaluronic acid (therapeutic aim).

Courtesy : C. Blanck, ICS

ELMO Specifications

| Plasma current | 0 – 35 mA |

| Platform diameter | Ø 60 mm |

| Process time | 1 – 6000 seconds |

| Chamber size | Ø 80 mm x 60 mm H |

| Vacuum control | Pirani Gauge |

| Working vacuum range | 1,0 – 0,1 mbar |

| Operation mode | Manual & Programmed |

| Gaz inlets | Ø 6 mm |

| Instrument size | 480 x 310 x 320 mm |

| Weight | 12 kg |

Vacuum Pump Specifications

| Displacement 50/60 Hz | 3,7 m3h-1 / 4,5 m3h-1 |

| Speed (Pneurop 6602) 50/60 Hz | 3,3 m3h-1 / 3,9 m3h-1 |

| Ultimate pressure | 2,0 x 10-3 mbar |

| Motor power 50/60 Hz | 450 / 550 W |

| Power connector 1-ph | IEC EN60320 C13 |

| Nominal rotation speed 50/60 Hz | 1500/1800 rpm |

| Weight | 25 kg / 55 lb |

| Inlet / Exhaust flange | NW25 / NW25 |

| Noise level | 48 dBA à 50 Hz |

| Operating temperature range | 12 – 40 °C |

Application notes :

Filamentous Condensation of DNA Induced by Pegylated Poly-L-lysine and Transfection Efficiency (44 downloads )

Rad51 Polymerization Reveals a New Chromatin Remodeling Mechanism (44 downloads )

The Srs2 Helicase Activity Is Stimulated by Rad51 Filaments on dsDNA: Implications for Crossover Incidence during Mitotic Recombination (45 downloads )

Contribution of DNA Conformation and Topology in Right-handed DNA Wrapping by the Bacillus subtilis LrpC Protein (44 downloads )